|

Diebold Safe & Lock Co., Canton, Ohio, 1894 - through today. Introduction Company History Diebold was founded in 1859 in Cincinnati, Ohio as the Diebold Bahmann Safe Company. Under the leadership of founder Charles Diebold, a German immigrant, the company's 250 initial employees began manufacturing safes and bank vaults out of a factory in Canton, Ohio. Most of the company's workers during the late nineteenth and early twentieth centuries were German immigrants. The company and its products became well known following the Great Chicago Fire of October 8, 1871. Diebold had manufactured 878 various safes and vaults that were located in buildings that the fire destroyed. All 878 safes and vaults survived intact. The following year Diebold moved its operations and headquarters to Canton to meet increased demand. In 1874, Diebold was contracted to build the word's largest safe, to be installed in the San Francisco branch of Wells Fargo. It took forty-seven railroad cars to ship the vault to San Francisco, California. In 1876, after becoming incorporated in Ohio the company changed its name to Diebold Safe & Lock Company. Diebold secured its first international sale in 1881, when it built a safe for the President of Mexico. Diebold debuted manganese steel doors marketed as TNT-proof in 1890, and in 1921, Diebold sold the world's largest commercial bank vault to Detroit National Bank. In 1930 Diebold introduced a "robbery-deterrent system for banks that flooded the bank lobby with tear gas" to help deal with robbers such as the infamous John Dillinger. In 1936, Diebold expanded its product lines by acquiring companies specializing in products such as paper-based filing systems, and it began developing armor plate for military tanks that year. Between 1939 and 1945, Diebold devoted 98 percent of its activities to the war effort. Among other projects, during World War II Diebold employed around 2,900 workers and "sold $65 million in armor plate for more than 36,000 U.S. Army scout cars," particularly the M2 Scout car model. In 1943, Diebold Safe & Lock Company changed its name to Diebold, Incorporated, in an effort to reflect the company's increasing diversification of products. The prohibition agent Eliot Ness was on the Diebold board from 1944 until 1951. Diebold earned a net income of $1.7 million in 1959. On April 27, 1964, Diebold went public. The company today is known known as Diebold Nixdorf and is in the Akron-Canton Ohio area. Diebold and their time locks It was not until 1894 that the company introduced its first time lock. Despite having waited so long to to enter the time lock market, Diebold was a keen observer of other companies' time lock research and would go on to parlay its renown in safe making into confidence in its time locks. With three seventy-two hour modular movements, the first Diebold model was the technical equal of any contemporary, offering unsurpassed reliability and ease of use for its time. The movements were very close in design to the Yale L-sized movement and would be used by Diebold in a number of later models. Like Yale's triple L and K time locks made during this same period, early Diebold movements were supplied by E. Howard. However, E. Howard's watch-making portion was taken over by the Keystone watch Case company in 1902, and like Yale, Diebold switched to Seth Thomas for its movements. Diebold's pre-1902 E. Howard movements all bear an attribution to Howard, either under the the winding arbor or behind the dial, whereas later Seth Thomas-made movements have no manufacturer's markings. Diebold is thought to have made thousands of the first model, the Type 1, and a few hundred exist today. The Type 3 designed to dog conventional boltwork has a far smaller production run and less than a hundred are thought to survive. (1) Diebold was a respected safe maker before entering the time lock business and so knew they would have a ready made market for their product. Furthermore, Diebold could make their time locks to the specifications of release and design to for their safes and vaults and so did not have to 'overdesign' their locks to operate other safe maker's specifications. I have seen many examples of Diebold safes that have other maker's time locks but I have yet to see a Diebold time lock in a safe that was not also from Diebold. Around 1908 Diebold bought out the Chicago Time Lock Company. Soon afterward they introduced their own branded time lock that was identical to Chicago's second version of their Marsh model time lock with only the name changed on the dial from Chicago Time Lock Company to Diebold Safe & Lock company. Then in 2001 Diebold bought the assets of Mosler Safe Company from bankruptcy. Today only Diebold and Sargent & Greenleaf still have branded time locks, but S&G is no longer an independent company having been acquired by Stanley Works, in 2005 and now makes their time locks in Lausanne, Switzerland. Diebold makes their time lock cases in the US but have Swiss-made movements.

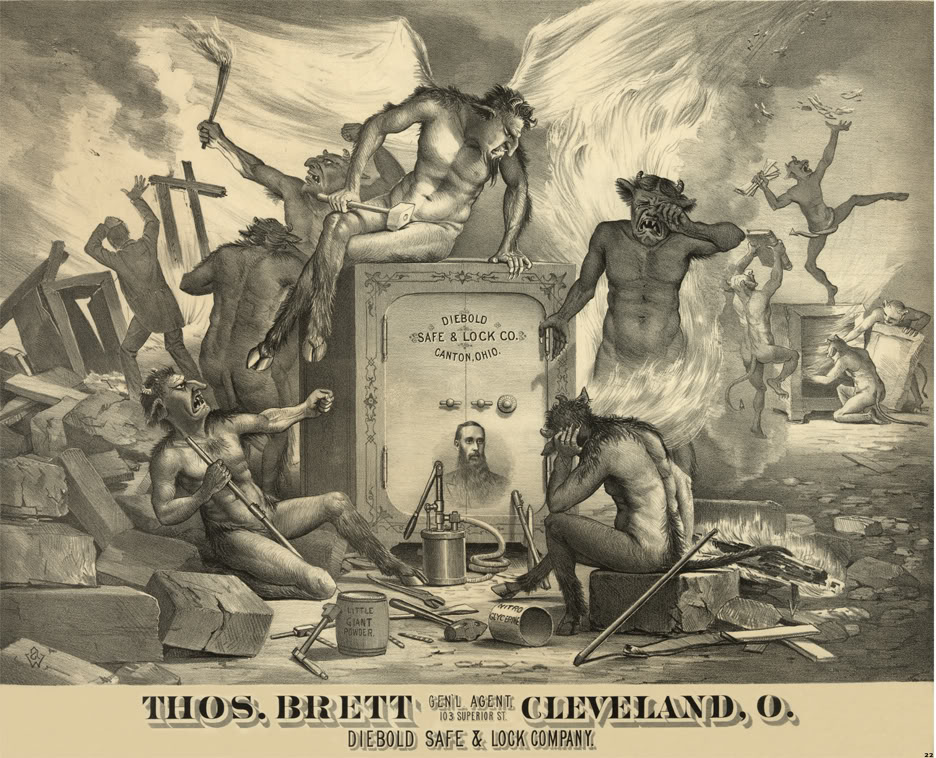

This advertisement from Thomas Brett a sales agent for Diebold, c. 1880 has a decidedly heavy religious theme, but at the same time humorous theme; invoking Hell complete with Devils that have horns, cloven hooves and tails, and surrounded by fire and brimstone! Look toward the left upper sector of the illustration showing a human displaying his grief over a broken, empty safe and just to drive home the religious theme, look at the burning timbers just to his right. There is no mistaking a nod to the crucifix. But when one looks at the despondent Devils futile attempts to break open the Diebold safe one just has to smile. Notice some of the implements they tried to use, blasting powder, nitroglycerine, hammers, chisels, pry bars, drill bits and what looks to be some sort of hydraulic device in front of the safe. Aside from the fire having the obvious connection to Hell, Diebold also made their first mark through the good performance of their safes in the Chicago Fire of 1871 so there is also this connection.

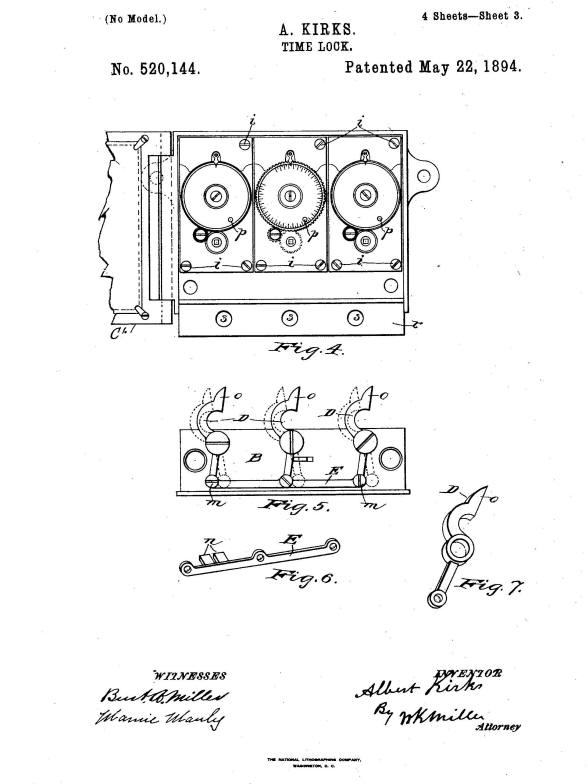

Albert Kirks' patent. Notice in the second illustration that the case, excluding the door, is not milled from one piece as is customary in most other time locks, but has the rear section as well as the lower front section supporting the snubber bar assembly are inserted as separate pieces, presumably this was a less costly way to make the case. This distinction was kept by Diebold throughout their production until the 1960's. Kirks was also known for his bolt motor patent which appeared with many Diebold time installations.

This photo shows the major components of a Diebold case. The case rear is a separate piece but is permanently riveted to the case sides.

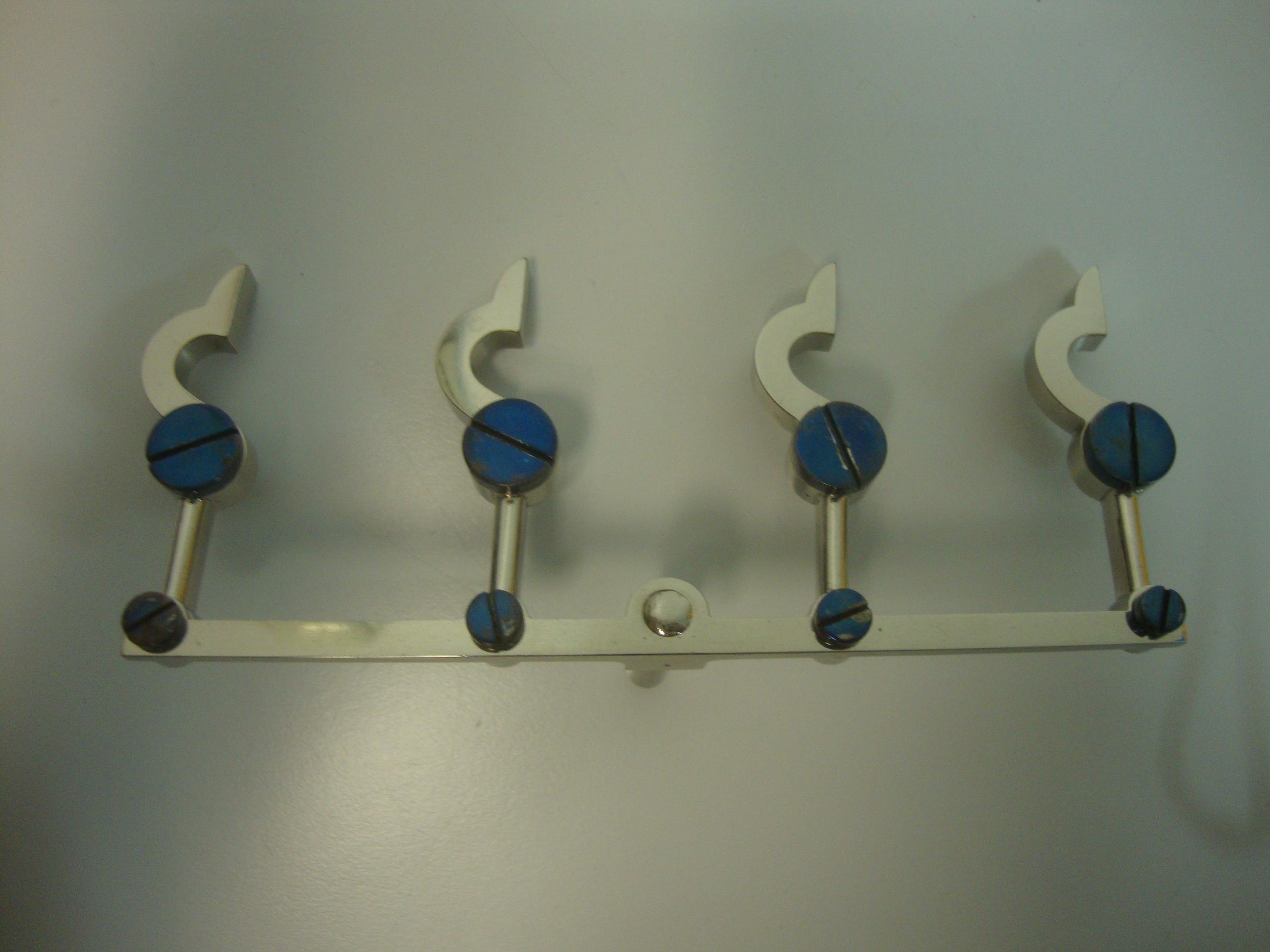

Diebold took extra steps in the look and finish of their time locks. The snubber bar is a sculpted rather than stamped out of flat stock and is a highly finished piece along with beautifully blued cheese head style screws. The second photo shows the snubber bar mounted to its elaborately decorated retaining plate.

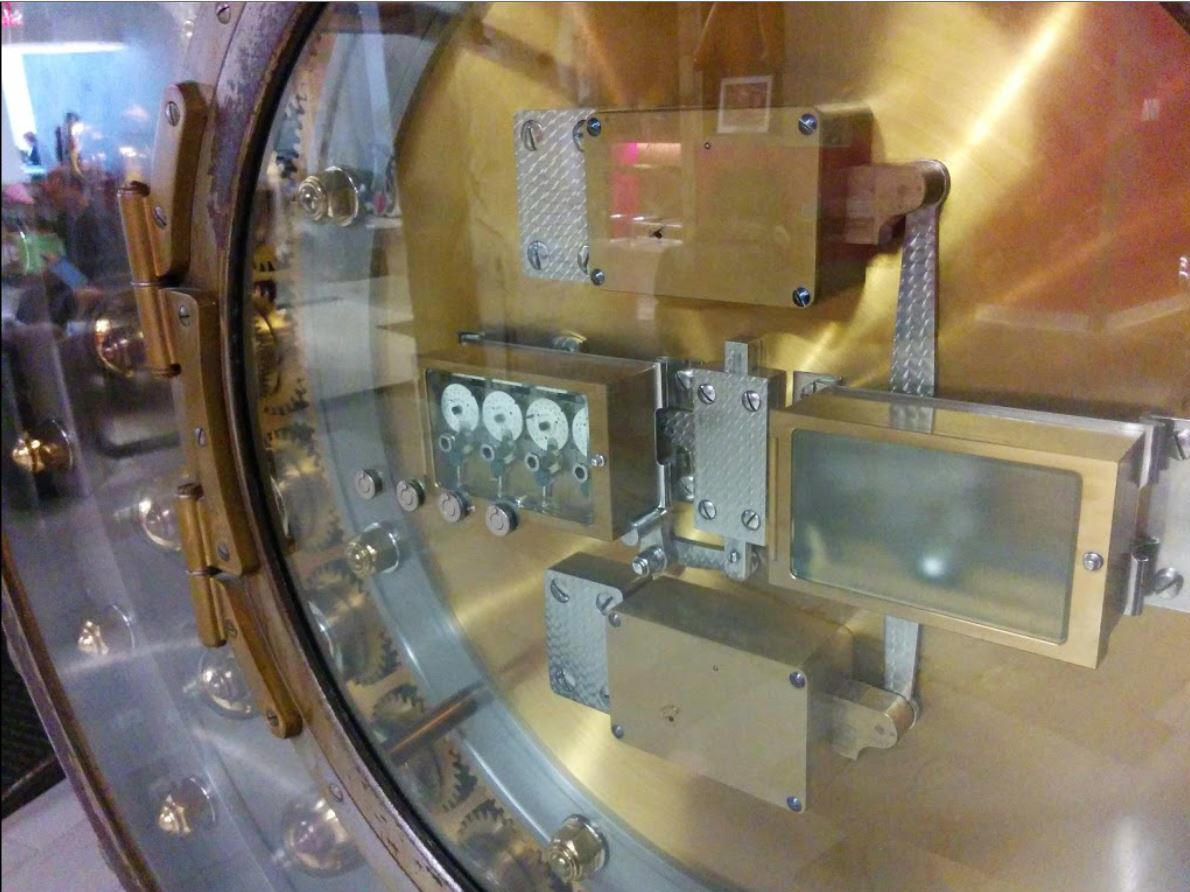

In this photo a Type 1 is converted to use as would be a Type 3 to dog conventional bolt works. On the lower right edge of the case one can see a lever which will raise or lower the center vertical rod between the two rectangular cases and which dogs the lever connected to the pair of combination locks. Diebold made relatively few of the Type 3 locks preferring to use this mechanism to apply their Type 1 time locks to directly dog bolt works. This was a practical option for Diebold since their locks were designed to operate on their own safes so there was no variability in design to make this conversion work as would be necessary for a variety of other maker's safe configurations. The other interesting observation here is the fact that there are winding holes through the time locks glass door. This was not the standard installation. Since the door to the time lock was easily opened with a push of the knob on the right hand door rail, it was expected that the operator would open the door to wind the time lock movements and so the glass would not have winding holes. Furthermore, there are four holes in the outer door glass. This is very curious as an extremely long key would be needed to reach each winding square from the outside of the vault door glass surface, perhaps three or more inches and this author has never seen this configuration in another installation. Apparently the proprietors wanted no access to any of the mechanism from the employee tasked to wind the time lock. Examples of Diebold time locks Type 1, bottom release for automatic bolt motors but with optional lever could operate manual bolt work

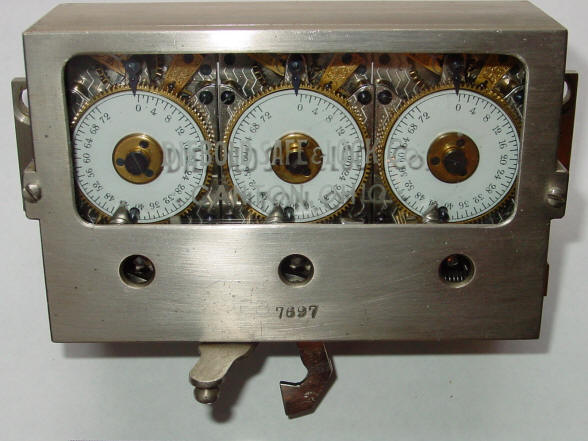

An early version having E, Howard movements and rosette logo on the snubber bar support plate.

These also had a floral design on the case sides. Soon after the rosette and floral designs were dropped in favor of a repeatable linear 'X' motif, second photo. The designs were acid-etched and gold plated. Sometime after 1900 the style changed to a less expensive bronze satin finish followed later, as design styles changed, to a satin silver color reflecting the sleek style of the 1920's. See below. In the early runs the movements were not strictly interchangeable and had holes in the rear plates that were staggered to correspond to pins in the case back; and was similar to the early S&G Triple A and B models using the same design. S&G introduced full interchangeability in 1895 with Diebold the following year. The type 1 was originally meant to operate an automatic bolt motor through a hook attached to the snubber bar and protruding through a slot in the case bottom. Later Diebold used a simple external modification to adapt the lock to operate on regular bolt work.

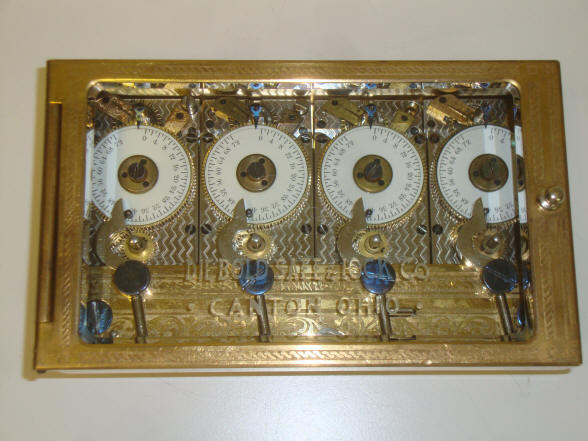

A four movement Type 1. Diebold was the only maker to employ a finished bevel glass for its door insert. They also did not use any locking device for their door; a break from usual practice. Type 3, for use with manual bolt work

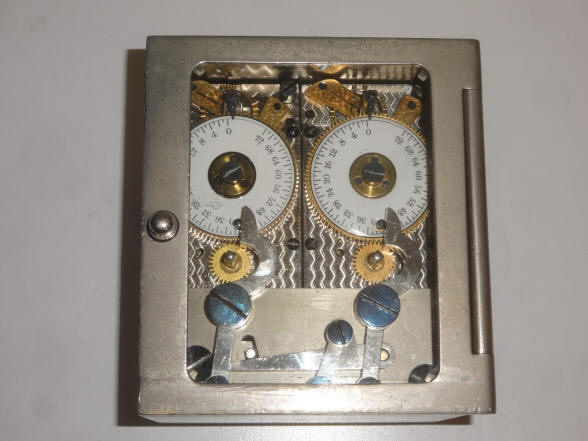

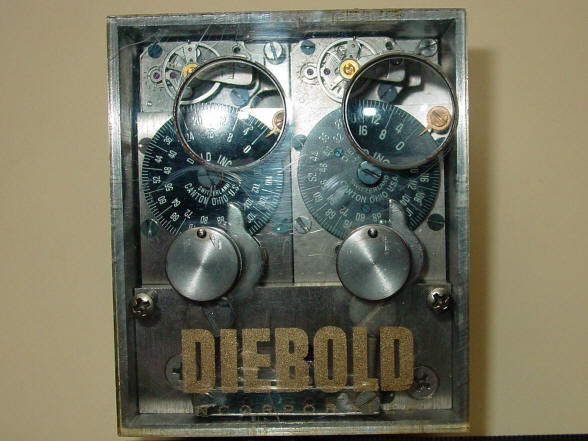

All four of these two movement examples were designed to operate on manual bolt work. This author has not seen an example of a two movement Type 1 for use on an automatic boltwork application. These examples show the progression of the case design throughout the standard Diebold model lines. The first has the original acid-etched gold plated art deco case design with logo etched bevel glass door and E. Howard movements. Next the less expensive satin bronze finish and plain glass door is substituted. By this time, post 1902, the movements were made by Seth Thomas. Some later models also had the side push button door release seen here. The third photo shows the same model with the silver satin finish but still retaining the standard door release knob. The satin silver finish was much more popular than the satin bronze in this company's as well as all other time lock makers product lines. The fourth photo shows a contemporary design beginning in the 1960's through today. A one piece steel box replaces the bronze multi-piece design with a screw-down plastic cover integral, molded dial magnifiers. The movements are Swiss made.

An early Type 3 with case decoration similar to that shown above for the Type 1. Notice the small L-shaped lever attached to the snubber bar that actuates the pin protruding through the snubber bar support plate on the left. This pin connects to the internal bolt dog that blocks the the square case opening where the door bolt work slides through as seen in the second photo.

These photos show the same progression in case and movement design as in the two movement examples above. Notice the handed position of the snubber bar as it relates to the dials in each. In the first photo the dials must rotate clockwise to engage the lever, this is a left-hand hinged door design. The next photo, while lacking a door because of the modern plastic cover, is a right hand hinge design with the movements rotating counterclockwise to engage the lever and is the same as the photo directly above the first one. The right hand hinge design was standard as it is today for refrigerators because most people are right-handed. All time lock makers produced models in a left and right hand door design to mirror the same needs of the vault door upon which it was mounted. This presents a design dilemma if the same time lock movement is used for both applications. On one hand, one would have the snubber bar move toward the right or the left depending on the location of the bolt dog within the case. But this means the time lock movements must either turn clockwise or counterclockwise. Diebold chose this route and had time lock movements made with an extra spur gear to reverse the dial rotation in their left hand door models and this clearly be seen in the first photo. Most other makers chose to have only one type of movement and use reversing lever mechanisms within the bolt dogging system to change the direction of the bolt dog. One time lock maker, Blake Bank Lock Inspection Co., took an entirely different approach making an entire time lock that had all the relevant parts reversible to accommodate a left or right hand hinge application. This design was unsuccessful since only one seems to have been made. TISCO line of time locks Beginning in 1895 and continuing through 1900 Diebold produced several time locks for use in their Tisco line of safes. Tisco stands for Taylor Iron & Steel Co. The Taylor Iron & Steel Co. was based in New Jersey between 1891 and 1912. They had acquired the American rights to the manufacture of non magnetic manganese steel in 1892 and built those safes for Diebold. Unique to the Tisco line, the time lock was designed to be mounted upside down, with the case door opening from the top down and the movements releasing when zero hours reaches the bottom of the dial. This may have minimized mounting space in the small area of the Tisco door.

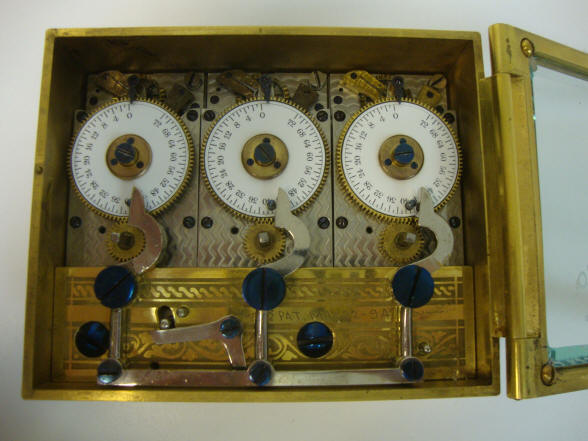

These photos show the two Tisco models produced by Diebold. |

(1) American Genius Nineteenth Century Bank Locks and Time Locks, David & John Erroll, p, 280