Complete lower movement main frame; hammer lift cam wheels - October 2009 B continues fabrication of the movement

frame base. First step is the curvature of the main frame base rails. Since this is a

fairly gentle curve, it requires a cutter mounted on a long arm to give a large diameter

swing. First two photos show the rail end shaped. The rest the shaping of the rail sides.

Below is depicted a novel way (at least as

applied to horology) of securing the various pieces of the frame together. (first

five photos). It’s also not unfamiliar to anyone who has had purchased

furniture from the large retailers like IKEA where it comes unassembled and the buyer has

to do this. Basically two parts are held together through the use of an anchor part, the

tongue, which has a hole. The mating part has a matching hole that has a slot into which

the tongue anchor piece hole fits. Into these two parts each with their holes matched up,

is inserted a shaped pin. This is basically a cam that when turned, will cause the tongue

with its hole centered between the slotted hole part to shift slightly drawing the two

parts securely together. This design allows one to hide what otherwise would be at least

two screws to secure the frame corners; leaving the method of fastening completely hidden.

It also allows for quick assemble-disassemble cycles, which makes the fabricator's job

easier. The cam is turned by a key inserted onto the squared arbor. Similar to design used

to secure pillars to base – see September. Notice the holes above and below the

tongue, second photo. These will have guide pins that will further strengthen the joint

(similar to the one positioned nearby on the horizontal rail surface). These pins are not

just slid into blind holes but are screwed into a threaded hole at their base.

Next three photos show the attachment of the lower base moldings.

Below are photos of some frame molding

details. This rich detail is the result of many separate machining steps and proliferation

of parts. The inside corners are particularly difficult to make (see last month’s

installment). The third photo shows what to me, is an outstanding example of B’s

quality of work. Even the inside base rim has a molding; something I would never had

expected. Next photo shows the frame near the movement to date. This is deceptive as

the frame is further back and thus looks smaller compared to the movement than it should.

Yes the parts do fit as depicted in the next two photos. One can see already how this

frame design allows for more of the wheel works to be seen than would otherwise be

possible in the former design employing a conventional plate and spacer design - even with

those plates skeletonized. Total frame weight approximately 77 lbs. or 35 kg. 126 parts so

far.

B sent some fancy finish photos of the

frame. He began the frame on the 7th of last month and has accomplished such a

beautiful object in just over a month. He will now break from any further fabrication of

the frame since he wants to make as many parts that will be between the plates as possible

so as to better know exactly how all of these will be planted before finalizing all of the

frame. This makes sense, although I think the frame design is pretty well already set!

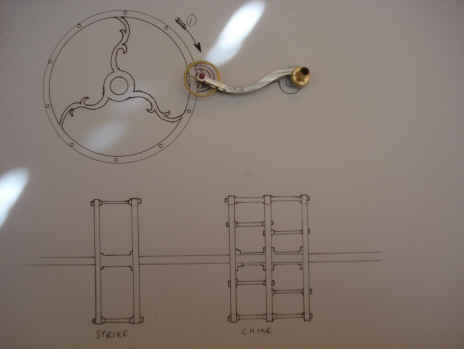

B sent a drawing of his concept for the strike wheels that will contain the lifting levers for the bell hammers. The fabrication of the strike cam assemblies now begins. Total of thirty pins in two different sizes. Notice that each is smaller than a match stick, second photo. The style of the wheels is in keeping with that of the balance arbor end plates.

Below is a playful photo showing the swarf

that is generated from the making of the screws for the quarter and hour strike hammer

lifting cam wheels. Shown is the basic rod stock from which the 100 screws needed for

these two assemblies were made.

Total parts excluding the arbor and collets

are 135. A conventional design would contain at most 15 to 20 parts with most containing

less than five when using a solid cam for the hammer lifters.

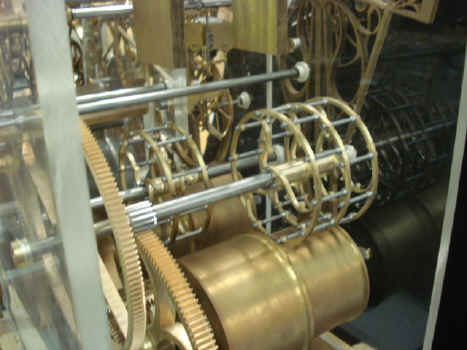

Below the hammer lifting cams are installed

into the movement; hour strike cam in background and quarter in foreground. The end view

shows that even the side that has ‘less components’ compared to the opposite

side that contains the time train remontoire, we are seeing this area filling in quite

nicely.

Astro_10-09_vid.mpg Astro_10-09_vid2.mpg Astro_10-09_vid3.mpg |