Redesign of grasshopper escapement assemblies - February 2009 The compositor springs were giving us trouble. There was too much action on the upper pallets to the extent that the recoil was too large and at times caused the jewel pallet to re-engage the escape wheel tooth before it could advance one step. B. tried to overcome this problem by adding a miniature fly to the assembly and thus introduce some drag; to dissipate the excess energy and slow the upper pallet. While it looked beautiful and added an extra visual feature to the design, in the end I rejected this. (See video below). First it was a bad idea to add friction to a system that we are trying to make as efficient as possible so as to maintain our eight day duration on a roughly 2.5 foot drop. Second it's poor engineering to add an additional device to negate the effects of one already installed. Third this fly will turn six revolutions - three forward and three backward - for each tick of the clock. There are 15,768,000 two second cycles per year meaning the fly will have to make 94,608,000 revolutions per year, reversing direction over 15 million times. This would not hold up for long! So I asked B. to go back to the drawing board and re-design the escapement pallet to be based solely on a gravity based system without the use of the compositor springs or fly fans. This is more in keeping with Harrison's original concepts. We also dispense with the compositor springs tipped with the tiny antifriction wheels - the only parts that were made with an EDM. As a result we lost several weeks of work.

We began the re-design, these are far simpler and now work with gravity rather than against it. Some flourishes were added to make the pallet reminiscent of a rooster, adding the tail feathers and of course the pallet stones themselves as the head and beak with a whimsical comb above all pecking away at the escape wheels.

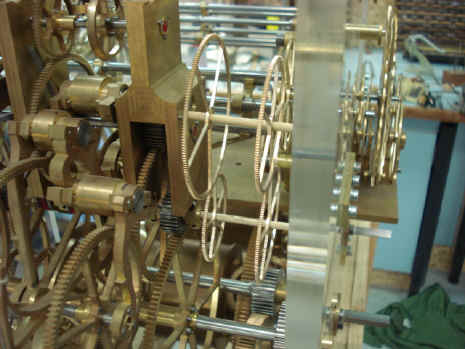

A look at the complexity of the escape pallets. A typical Graham deadbeat escapement pallet unit consists of one part, even the Denison gravity escapement has less than a dozen parts. Each of these pallet assemblies contains 27 complicated parts, 54 for the pair.

A close up of one of the pallet 'rooster' heads. Notice the care taken to give a reveal between the neck and the area that supports the larger jewel. Nearly all other fabricators would have had this made in one plane.

A close up of B.'s re-designed barber pole. I am not sure I like this, as it does not show the rotation as clearly as the earlier four-sided version. These are designed to show the power movement from the source to the end point. In this case from the remontoire to the fly fans. There will also be another set from the remontoire to the dual escapement wheels.

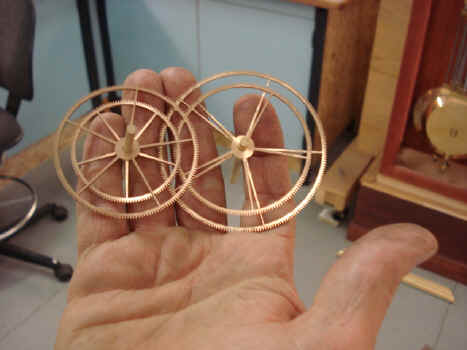

Some examples of B.'s beautiful wheel work. His signature examples of thin rims and spoke work.

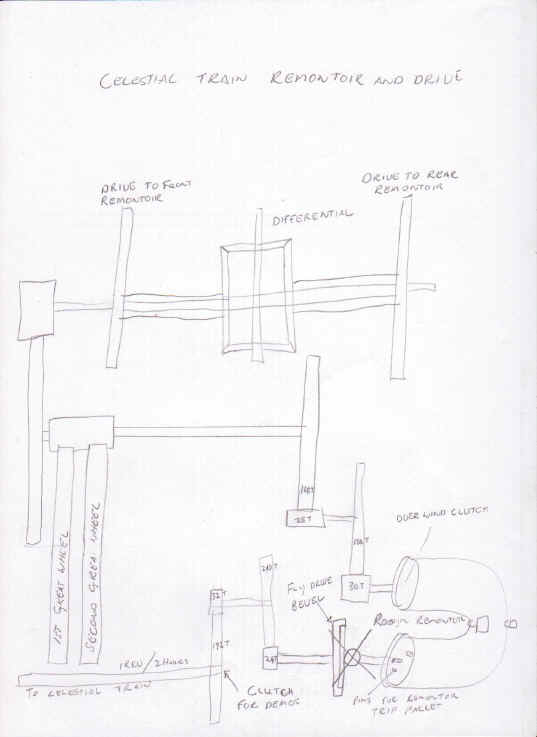

Below is the initial concept for the Robin type remontoire that will be used to trip the celestial train each minute. This will separate the drive of the celestial train from that of the going train. There will be safety clutch employed in the case of the celestial train jamming up.

Astro_02-09_vid.mpg Astro_02-09_vid2.mpg Astro_2-09_vid3.mpg Astro_02-09_vid4.mpg |